Molly Maxted demonstrates the old restaurant stock pot where she mixes her soaps. Home Made

Molly Maxted's soaps

story and photos by Sheela McLean

In a workshop in the hills west of the Chewuch River, Molly Maxted makes soap. In her sweet-smelling, wood-heated and orderly workshop she stirs up 18 different kinds, from ‘Calendula’ and ‘Simple Soap’ for very dry and sensitive skin, to ‘True Grit’ designed to get that sticky stuff off of hard-working hands.

Maxted makes Molly’s Soap in batches in a 1950’s-era restaurant stock pot which has a thermostat and an inlet for water.

“The soap takes about an hour in the kettle, after everything has been brought to the correct temperature,” she said. “After the mixture thickens…it is poured into (big block molds) and covered for 24 hours or more.”

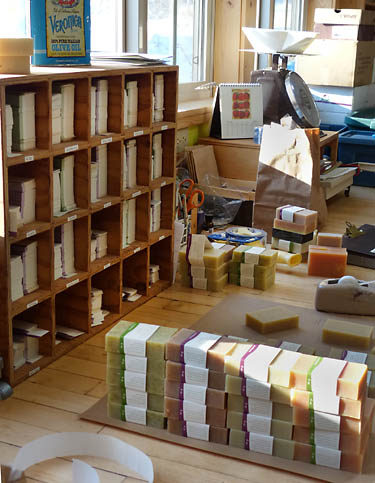

When the soap comes out of the block molds it rests for a day or two before Maxted cuts it into ingots, and then it rests again before each ingot is cut into seven or eight bars and stacked in the curing crates. After curing for about a month, it's ready for sale or to be stored in paper until it sells. “I label the bars right before they're shipped or delivered,” Maxted said.

Overall, soap-making is low-tech Maxted explained, and “it’s not a get-rich quick scheme.”

Molly Maxted stands near a crate of her soap, curing nicely in the dry Methow Valley air. The basis of Maxted’s soap is olive, palm or coconut oil mixed with a little lye. Soap works because of the marriage of the lye’s alkalinity and acids of the fats, Maxted explained. Together, through a process called ‘sponification,’ the chemicals break down the surface tension of water, so that it will rinse away the oils and dirt.

When she first mixes the products that make soap, the mixture rises to 95 or 100 degrees Fahrenheit, naturally. In spite of the heat given off, Maxted’s soap is called “cold processed.” Soap made in big operations is manufactured at a higher temperature, she said, so that the valuable glycerin can be extracted and sold separately. Maxted leaves in the glycerin, and adds other products to the different soaps that “do a little something for the skin.”

Maxted said that homemade soap wasn’t so popular when she first became interested. “People back then were afraid to use homemade soap,” she said, because of the lye that is required.

Maxted grew up in California, and went to school in Eugene, Oregon, where she majored in Romance languages. (“I wish I had taken chemistry,” she said.)

“There weren’t books then on how to make soap,” she said, but in 1975 she and a good friend went ahead and tried anyway, using lard and tallow and a can of lye. The soap she and her friend made were to help make ends meet financially while they were in school. The first batch wasn’t so great, but “we tweaked it around,” and the second batch was pretty good.

Soap resting in the sun on a workbench is ready to be sold. When Maxted moved in 1976 to Curlew, she continued to make soap for herself and her family while she also worked other jobs—in restaurants for example. Curlew wasn’t a great place to sell soap, there were only 200 residents and she lived out of town anyway.

But she kept making soap for herself and her family, and friends. “Then I thought ‘mail-order soap’” she said, and she started the full-on retailing in about 1982 with five kinds of handmade soap. “Then I discovered craft fairs.” And by the time she moved to Seattle in the early 1990s “I could really market,” she said.” Her business grew to include employees and products besides soap. In a peak year, she probably sold 20,000 to 30,000 four-ounce bars of soap, she said.

In 2010, after Maxted had moved to the Methow Valley, she found a suspicious lump in her chest. It turned out to be breast cancer, a very aggressive form. “I had to scale back” while in treatment she said. Though she’s just over three years without a re-occurrence, she is still using the business model that she reduced to then, and she appears content with her scaled-down business, Molly’s Soap. She sells wholesale to food co-operatives in Sacramento and in the Skagit, to Sunny Farms in Sequim, and to various gift shops. She supplies Methow Valley stores with her soap and does business on-line with mail orders from her website.

She used to send out a mail order flyer, but now she serves long-time customers and advertises to new customers on the internet. “I’ve had great customers,” she said, and still sells to people that she first sent soap to in the 1970s. Many of them she thinks of as “friends that I’ve never met.”

“I’m sort of a hermit by choice,” Maxted explained. She and her partner, Shane Ruoss, a building contractor, keep bees, have about 30 fruit trees and a large garden. Maxstead said soap-making now takes up half to three quarters of her time.

Some of the carefully mixed additions of different substances and scents used in Molly's soaps. Some of the carefully mixed additions of different substances and scents used in Molly's soaps.

12/29/2013

see past stories in the archive >>

|